This austenite crystalline structure is achieved by sufficient additions of the austenite stabilizing elements nickel, manganese and nitrogen. Due to their crystalline structure, austenitic steels are not hardenable by heat treatment and are essentially non-magnetic.There are two subgroups of austenitic stainless steel. 300 series stainless steels achieve their austenitic structure primarily by a nickel addition while 200 series stainless steels substitute manganese and nitrogen for nickel, though there is still a small nickel content.300 series stainless steels are the larger subgroup.

Связаться сейчас

316L Super Austenitic Stainless Steel316L Super Austenitic Stainless Steel Scope of application:Corrosion resistance, atmospheric corrosion resistance and high temperature strength are particularly good, which can be used in harsh conditions; Excellent work hardening (non-magnetic).

Связаться сейчас

The 904L stainless steel plate mainly uses a special corrosion-resistant alloy, mainly because the carbon content of this alloy is very low, which is several times lower than other models, so the probability of being corroded is greatly reduced. . We all know that in some areas with harsh environments, when stainless steel plates are used, the most worrying thing is that they will be corroded. Some of them will be corroded if they cannot last for a long time.

Связаться сейчас

317L Austenitic Stainless Steel Wire 317L Austenitic Stainless Steel Wire ’s Mechanical properties:317L mechanical properties: ys (MPA) ≥ 176, TS (MPA) ≥ 480, EL (%) ≥ 40, HV ≤ 200317L Austenitic Stainless Steel Wire 's chemical composition317L chemical composition: carbon (c) ≤ 0.030, manganese (MN) ≤ 2.00, nickel (Ni) 11.0 ~ 15.0, silicon (SI) ≤ 1.00, phosphorus (P) ≤ 0.045, sulfur (s) ≤ 0.030, chromium (CR) 18.0 ~ 20.0, molybdenum (MO) 3.0 ~ 4.0Product Parameter:Weight1000(kg/km)Diameter0.2-14mmLengthAs requirementsMaterial201,301,302,303,304,304L,316,316L,317L,321,308,308L,309,309

Связаться сейчас

These grades of austenitic stainless steels are the most versatile and widely used stainless steels. They exhibit excellent corrosion resistance to a wide range of corrosive environments.

Связаться сейчас

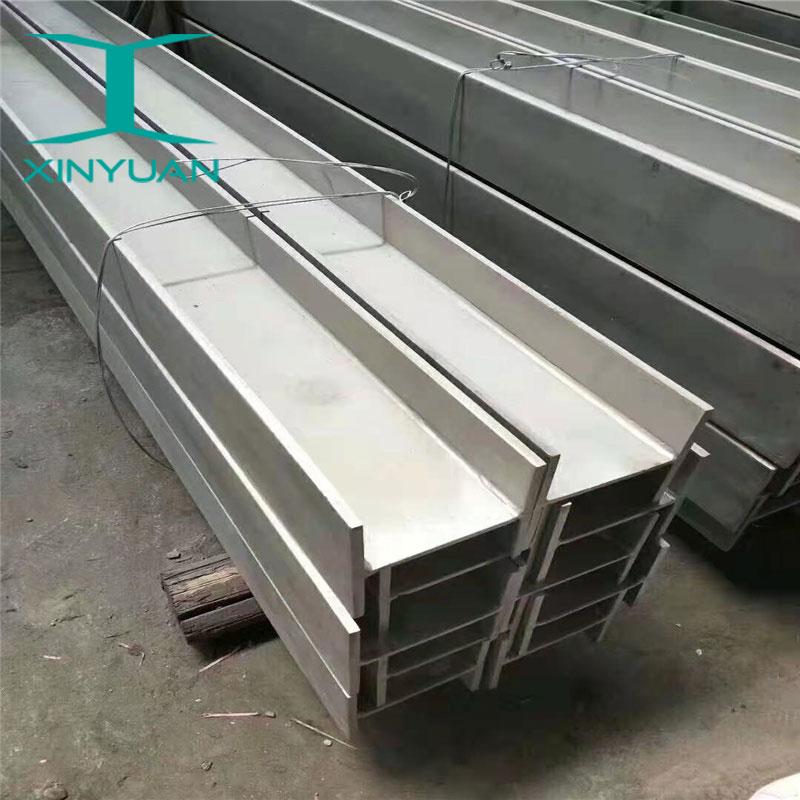

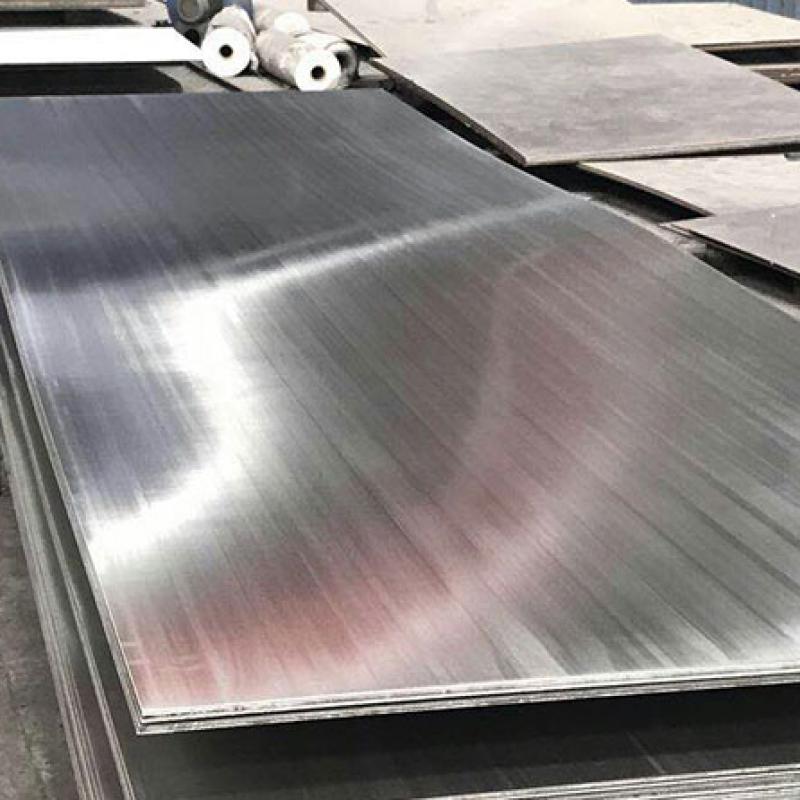

Duplex polished ss 1mm 3mm 5mm 2205 2507 cold rolled stainless steel coilProducts DescriptionProduct Namestainless steel plateThickness0.1~150mmWidth600mm,1000mm,1219mm,1500mm,1800mm,2000mm,2500mm, 3000mm, 3500mm,etcLength2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etcStandardASTM GB/T JIS4 ASME BS DIN ENMaterial 200 series: 201/202 300 series: 301/304/304L/305/309S/310S/316/316L/316LN/316Ti/317/317L/347/347H 400 series: 405/409/409L/410/420/430/440C/444/4447 600 series: 630/631 duplex stainless steel: 2205/2507/2520 super stainless steel: 904LFeature

Связаться сейчас

Product SpecificationUnit Pipe Length3 meter, 6 meter, 9 meter, 18 meterMaterialStainless SteelProduct DescriptionGradeTensileUltimate/MinYield/MinElongation/Min-KSIMPAKSIMPA%304755153020535304L704852517035These grades of austenitic stainless steels are the most versatile and widely used stainless steels.

Связаться сейчас

Types 309 and 309S are austenitic chromium-nickel stainless steels that provide excellent corrosion resistance and heat resistance plus good strength at room and elevated temperatures. Type 309S is identical to Type 309 except for a lower carbon content that minimizes carbide precipitation and improves weldability.

Связаться сейчас

1. Compared with 316L and 317L austenitic stainless steel,2205 alloy has better performance in corrosion resistance and crack corrosion, it has high corrosion resistance, compared with austenite, its thermal expansion coefficient is lower, higher thermal conductivity.2. Compared with austenitic stainless steel, the compressive strength of duplex stainless steel 2205 alloy is twice that of austenitic stainless steel. Compared with 316L and 317L, the designer can reduce its weight.

Связаться сейчас

Most people have something made of stainless steel in their homes, whether it’s a kitchen appliance, some hardware, or even a piece of décor. Almost everybody knows what stainless steel is and what it looks like. Something that surprises many people is finding out there are actually multiple kinds of stainless steel. Check out this guide to learn more about the different types of stainless steel. Austenitic Austenitic stainless steel is designed to be nonmagnetic. A great example of an everyday application for austenitic stainless steel is a stainless steel oven.

Связаться сейчас

254SMO is an austenitic stainless steel. Because of its high molybdenum content, it has very high resistance to spot corrosion and crevice corrosion. Main ingredients:254 smo carbon (C) 0.02 or less, manganese (Mn) of 1.00 or less, nickel (Ni) 17.5 ~ 18.5, silicon (Si) of 0.8 or less phosphorus (P) of 0.03 or less, sulfur (S) of 0.01 or less, chromium (Cr) 19.5 ~ 20.5, copper (Cu) 0.5 ~ 1.0, molybdenum (Mo) 6.0 ~ 6.5 National standards: UNS S31254, DIN/EN 1.4547, ASTM A280, ASME SA-240 Welding material: ERNiCrMo-3 wire, ENiCrMo-3 electrode Product Name254smo st

Связаться сейчас

ER316/316L is used for welding types 316 and 316L stainless steels. It has a maximum carbon content of .03% to reduce the possibility of formation of intergranular carbide precipitation. This low carbon alloy is not as strong as 316H at elevated temperatures.Typical Applications: primarily used for welding low carbon molybdenum bearing austenitic alloys AWS Class: ER316/316LCertification: AWS A5.9/A5.9M:2006Alloy: ER316/316LAWS/ASME SFA A5.9&nb

Связаться сейчас

Type 301 is a chromium nickel austenitic stainless steel capable of attaining high strengths and ductility by cold working. It is not hardenable by heat ...Type 301 is corrosion resistant in many environments, but the corrosion properties are less than that of 304/304L stainless steel.

Связаться сейчас

Austenitic stainless steel refers to stainless steel with an austenitic structure at room temperature. When the steel contains about 18% Cr, 8%-25% Ni, and about 0.1% C, it has a stable austenite structure. Austenitic chromium-nickel stainless steel includes the famous 18Cr-8Ni steel and the high Cr-Ni series steel developed by adding Cr and Ni content and adding Mo, Cu, Si, Nb, Ti and other elements on this basis. Austenitic stainless steel is non-magnetic and has high toughness and plasticity, but its strength is low. It is impossible to strengthen it through phase transformation.

Связаться сейчас

OverviewStainless Steel Sheet Grade 304 is known to be the most widely used and flexible austenitic form of stainless steel. It contains 8% nickel and 18% chromium, making it ultra resistant to corrosion and oxidation.It is also highly durable and can be fabricated with ease.

Связаться сейчас

347 347H tp347h is a stable austenitic chromium steel that contains niobium and eliminates carbide precipitation, thus eliminating intergranular corrosion. Alloy 347 is stabilized by the addition of chromium and tantalum and provides higher creep and stress-fracture properties than alloys 304 and 304L, which can also be used for exposures requiring attention to sensitization and intergranular corrosion.

Связаться сейчас

301 stainless steel bar is a metastable austenitic stainless steel with complete austenitic structure under the condition of full solution.

Связаться сейчас

The Stainless Steel 904L Pipe & Tube is one great austenitic stainless steel alloy which is renowned for its amazing corrosion resistant properties. Moreover, it features some low carbon, and thus, it is the updated version of the same 904 range. It offers numerous benefits to the users; therefore, it is seen applied in various industries.

Связаться сейчас

Type 301 is an austenitic chromium-nickel stainless steel that is available in the annealed and cold worked conditions. In the annealed condition, Type 301 offers the highest level of stretch formability of any stainless steel and in the heavily cold worked condition offers the highest strength level of any 300 series stainless steel. Type 301 is non-magnetic in the annealed condition but becomes magnetic as a result of cold working.Type 301 is corrosion resistant in many environments, but the corrosion properties are less than that of 304/304L stainless steel.

Связаться сейчас

Duplex stainless steel tube has good welding performance, compared with ferritic stainless steel and austenitic stainless steel, it is not like the welding heat affected zone of ferritic stainless steel, because of the severe coarsing grain and the plastic toughness is greatly reduced, nor like austenitic stainless steel, is more sensitive to welding hot crack.Because of its special advantages, duplex stainless steel is widely used in petrochemical equipment, seawater and wastewater treatment equipment, oil and gas pipelines, papermaking machinery and other industrial fields.

Связаться сейчас

s31803 Duplex stainless steel is a kind of Medium alloy stainless steel,it's PREN value is 32-33, and its corrosion resistance is between AISI 316L and 6%Mo+N austenitic stainless steel.Duplex stainless steel has the characteristics of both austenitic stainless steel and ferritic stainless steel because it has austenite + ferrite dual-phase structure, and the content of the two phase structures is basically the same. The yield strength can reach 400Mpa ~ 550MPa, which is twice that of ordinary austenitic stainless steel.

Связаться сейчас

Stainless steel grade 301 is a commonly available austenitic stainless with good corrosion resistance and elevated carbon to allow for cold working to a variety of tempers.

Связаться сейчас

301 stainless steel strip is a kind of metastable austenitic stainless steel, which has a completely austenitic structure under the condition of full solution. Among the stainless steels, 301 is the steel that is most easily strengthened by cold deformation. Cold deformation can increase the strength and hardness of the steel and retain sufficient plasticity and toughness. In addition, this steel has good rust resistance under atmospheric conditions.

Связаться сейчас

GH3039 is a single-phase Austenitic solid solution reinforced alloy with moderate thermal strength and good thermal fatigue properties below 800℃ and good oxidation resistance below 1000℃. Long-term use of stable structure, but also has good cold formability and welding performance. Suitable for aero engine combustion chamber and afterburner parts used for a long time below 850℃.

Связаться сейчас