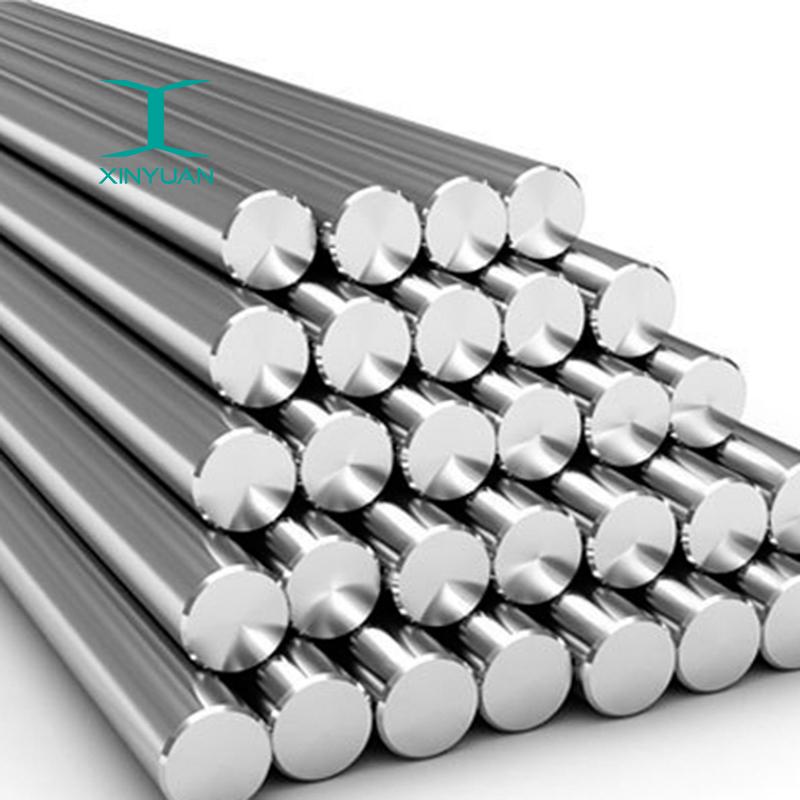

Application field:(1)instrument transformerd(2)rader pulse transformers(3)Transducers(4)Shielding(5)tape recorder head laminations and so onProduct Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm (All sizes can be customized)Forged Bar: 180~400mmLengthCustomizedApplicationAuto, turbines, blades, powder

Связаться сейчас

Alloy 718 (UNS N07718) is a high-strength, nickel-based superalloy made for long-term use in temperatures ranging from cryogenic up to 1200°F.

Связаться сейчас

718 Nickel-based alloyProduct description718 Nickel-based alloy is specifically γ '[ Ni3(Al, Ti, Nb)] Nickel based high temperature alloys with getting older reinforcement have proper corrosion resistance and oxidation performance beneath 980 °C, excessive strength below 800 °C, and proper rest resistance underneath 540 °C.

Связаться сейчас

The alloy is resistant to high temperature corrosion properties such as oxidation and carbonization. The alloy is *** resistant to corrosion in hot corrosion areas such as sulfide environments, especially oxidation and carbonization up to 1100°C cycles. These corrosion resistance coupled with excellent mechanical properties make this alloy particularly suitable for high temperature applications.

Связаться сейчас

This nickel based alloy produced in the form of rounds, squares, hexagons, rectangles as well as Alloy 601 Uns N06601 Cold Finished Bar apart from cold- worked wire, have been covered in the ASTM B166 specification.

Связаться сейчас

ncoloy617/alloy617 alloy processing and welding properties: the alloy is easy to process in a variety of hot and cold processing, although due to the high strength, high-power equipment is required. Product Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm (All sizes can be customized)Forged Bar: 180

Связаться сейчас

Alloy 400 from NeoNickel has superb corrosion resistance, particularly in neutral and alkaline salts. It is also one of a limited number of alloys that can be used in conjunction with hydrofluoric acid and fluorine. With high nickel content, this alloy is immune to chloride-induced stress corrosion cracking.

Связаться сейчас

Copper Nickel Alloy Strip CoilCompany ProfileSince its establishment Tianjin Xinyuan Stainless Steel Co., Ltd. has been steadily seeking progress with the care and support of colleagues and customers from all walks of life, and has developed into a comprehensive enterprise integrating stainless steel material processing and sales agents.Main materials: 201, 301, 304 (0Cr18Ni9), 304L (00Cr19Ni10), 321 (1Cr18Ni9Ti), 316 (0Cr17Ni12Mo2), 316L (00Cr17Ni14Mo2), 309S (0Cr23Ni13), 310S (0Cr25Ni20), 904L (00Cr20Ni25Mo4.5Gu) 316 , 317L, 317H, 304H, (SUS304, 321, 316, 310S, etc.).

Связаться сейчас

The C276 alloy (UNS N10276) is used in chemical processing, pollution control, pulp and paper production, industrial and municipal waste disposal, and recovery of "sour" natural gas.

Связаться сейчас

Alloy K-500 (UNS N05500) is a nickel-copper alloy.

Связаться сейчас

GH3044 is a solid solution strengthened nickel-based anti-oxidant alloy with high plasticity and moderate thermal strength under 900℃, and has excellent oxidation resistance and good stamping and welding process performance. It is suitable for manufacturing the main combustion chamber and afterburner parts, heat shield and guide blade of aviation engines working under 900℃ for a long time.

Связаться сейчас

Hastelloy plates are suitable for various chemical industries containing oxidizing and reducing media. The higher molybdenum and chromium content enables the alloy to resist chloride ion corrosion, and the tungsten element further improves corrosion resistance. At the same time C-276 Hastelloy tube is one of only a few materials resistant to corrosion by moist chlorine gas, hypochlorite and chlorine dioxide solutions?

Связаться сейчас

Section shrinkage ψ(%):134 degrees, aging ≥ 61Density melting point for Young's modulus and Poisson's ratio, yield strength, tensile strength, elongationProduct Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm (All sizes can be customized)Forged Bar: 180~400mmLengthCustomizedApplicationAuto, turb

Связаться сейчас

Inconel600 alloy has satisfactory thermal strength and high plasticity below 800C.

Связаться сейчас

The Incoloy 800HT is resistant to many corrosive media. Its high nickel content makes it have good resistance to stress corrosion cracking under water-based corrosion conditions. High chromium content makes it have better resistance to spot corrosion and crevice corrosion cracking. The alloy has good resistance to nitric acid and organic acid, but limited resistance to sulfuric acid and hydrochloric acid. Excellent corrosion resistance in oxidizing and non-oxidizing salts, except for the possibility of point corrosion in halides.

Связаться сейчас

Incoloy 926 nickel-based alloy application areas:1、Fire protection system, seawater purification system, hydraulic and perfusion piping system in marine engineering:2、Bleaching pool in cellulose pulp production;3、Polishing rods in corrosive oil wells:4、Hose system in marine engineering:5、Piping, joints, airflow system in acid gas production, etc;6、Components in flue gas desulfurization system;7、Evaporator, heat exchanger, filter, mixer, etc.

Связаться сейчас

Alloy X-750 exhibits excellent oxidation resistance to combustion gases at ambient temperatures up to 1600°F(870°C).Product Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm (All sizes can be customized)Forged Bar: 180~400mmLengthCustomizedApplicationAuto, turbines, blades, powder and engines,etcFeatureHi

Связаться сейчас

G-30 Nickel Base Alloy PipeHastelloy G30 Seamless Pipes is a corrosion resistant alloy of nickel – chromium – molybdenum that is particularly appropriate for use in oxidizing acids. Hastelloy G30 Seamless Tubes is a excessive Nickel primarily based alloy which suggests best corrosion resistance over most different Nickel and Iron based totally alloys in phosphoric acids as properly as many complicated environments containing incredibly oxidising acids such as nitric, hydrofluoric and sulphuric.

Связаться сейчас

Alloy B-2 is a nickel-molybdenum alloy with significant resistance to reducing environments, such as hydrogen chloride gas and sulphuric, acetic and phosphoric acids. Hastelloy® B-2 provides resistance to pure sulphuric acid and a number of non-oxidizing acids. The alloy should not be used in oxidizing media or where oxidizing contaminants are available in reducing media.

Связаться сейчас

This alloy has the following properties.1. High resistance to pitting and crevice corrosion in halide media and acidic media containing H2S2. Effective resistance to chloride ion stress corrosion cracking in practical applications3. Excellent corrosion resistance to all kinds of corrosion in the usual oxidizing and reducing environment4. Mechanical properties are improved compared to Cronifer 1925 LC-Alloy 904 L5.

Связаться сейчас

Characteristic as below:(1)high permeablity(2)high saturation magnetostriction(3)low hysteresis-energy loss(4)low eddy-current loss in alternating flux(5)low curie temperature(6)vonstant permeablity with changing temperatureTypeNickel Alloy Sheet/PlateThickness0.8-36mmLength3000mm, 5800mm, 6000mm,etcWidth1000mm,1500mm,2000mm,etcStandardASTM,AISI,JIS,DIN,ENApplicationConstruction,Ship,Boiler,Machinery,etcCertificationISO,SGS,TUVTechniqueCold Rolled/Hot RolledEdgeMill Edge/ Silt EdgeGradeHastelloy: Hastelloy B/ -2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N/g;etcInconel 600/601/602CA/617/625/713/71

Связаться сейчас

Alloy 625 exhibits excellent corrosion resistance in many media.

Связаться сейчас

600 alloy (UNS NO6600) The alloy is widely used in the chemical industry for its strength and corrosion resistance. Applications include heaters, stills, bubbles and condensers for fatty acid processing; Evaporator tubes, segments and spalling pans for the manufacture of sodium sulfide; And equipment for processing plants.

Связаться сейчас

Bars are the most common raw material used by industries in various shapes and sizes, one such shape of the bar is Alloy 926 Round Bar. The most common shapes of Bars are Alloy 926 Round Bar, Alloy 926 Square Bar, Alloy 926 Rectangle Bar, and Alloy 926 Hex Bar.

Связаться сейчас