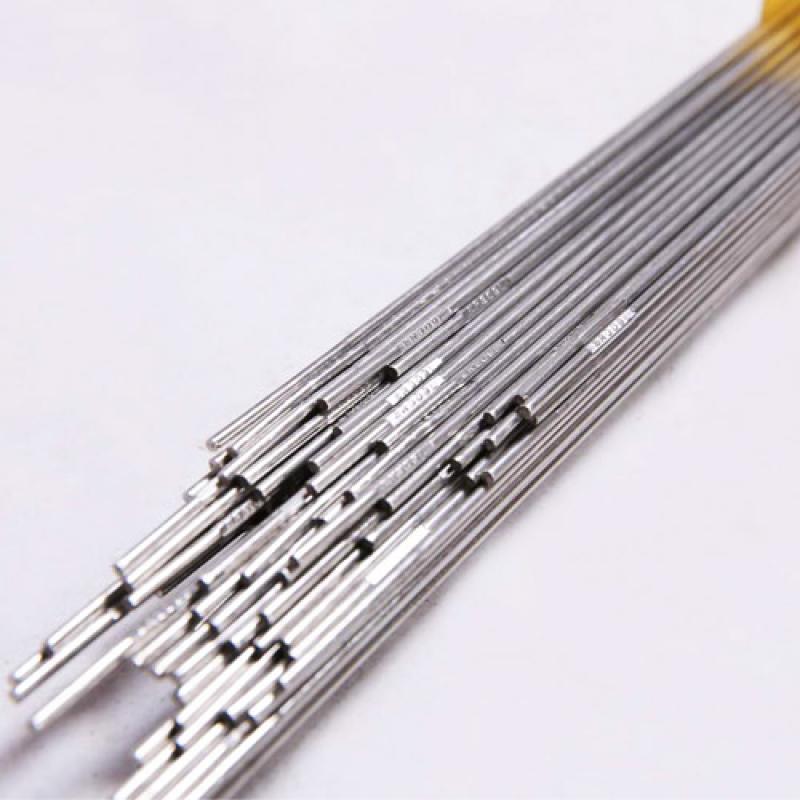

Products InfomationApplication:Used to weld ship building steel(A,B,D,E,A36,D36,E36)and equivalent mild steel or 550Mpa grade mild alloy steel, such as container building, construction machine, railway construction, pressure vessel for semi-auto or automatic gas shielded welding.It HAS excellent welding process performance, stable arc combustion, less spatter, beautiful weld forming, small stomatal sensitivity of weld metal, good all-position welding process, suitable for a wide welding current range.

Связаться сейчас

Supplier Of Socket Weld Flange Wall Thickness, Socket Weld Flange Class 900,Socket Weld Flange Class 2500, Socket Weld Ring Joint Flange, Gasket For Socket Weld FlangeSocket Weld Flanges UK, PN16 Socket Weld Flange Dimensions,Socket Weld Flange Welding, 2 inch socket weld flange, 4 bolt socket weld flange, socket weld companion flange, socket weld tube flange, 6 inch socket weld flangeANSI/ASME B16.5 Socket Weld Flange SpecificationDimensions ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom DrawingsSize 1/2″ (15 NB) to 48″ (1200NB)Class150 LBS, 300 LBS,

Связаться сейчас

Stainless Steel Butt Weld ElbowPackaging Details:Standard seaworthy package or as your requiredPort :Tianjin or as your requiredProducts DescriptionProduct NameANSI B16.9 Butt Weld Stainless Steel 90 Degree LR ElbowSize1/2"-48"MaterialStainless SteelPackagingWooden Case/Wooden PalletsStandardANSI ,ASME, EN,DIN, JISRadiusLong, Short ThicknessSCH5S-SCHXXSOthersSpecial design available according to your requestProduct photoProduct Advantage:1.

Связаться сейчас

Customized ANSI 150lb-2500lb 1/2"-72" SS WN Flanges Stainless Steel Weld Neck FlangeItemDescriptionBasic InformationMaterial GradeWP304 , WP304L , WP304H , WP316 , WP316L , WP316Ti , WP309S , WP310S , WP321 , WP321H , WP347 , WP347H , F304 , F304L , F304H , F316 , F316L , F310S , F321 etcSize1/2" to 48" Sch 5S to XXSStandardASTM A403 etc .Process MethodForged / CastingIndustry & AdvantageApplicationa) Connect pipesAdvantagea) High technology ; good surface ; high quality etcTerms & ConditionsPrice ItemFOB , CFR , CIF or as negotiationPaymentT / T , LC or as neg

Связаться сейчас

Stainless Steel PipeFormWelded and Seamless in Round.ApplicationFluid & Decorative.Size RangeDN15 – DN600.Grades304/304L & 316/316L.321,309S,310S,347H,2205,2507,254SMO, Wall ThicknessSch 10S, 40S & 80S.FittingsButt Weld, Screwed & Socket Flanges (ANSI, Table E & Table D).ProcessingCut-to-length & polishing.The information provided is for standard stock product and does not encapsulate all available combinations.

Связаться сейчас

Using 316L stainless steel, no post-weld annealing is required.

Связаться сейчас

ASME B16.5 SpecificationsSpecificationASME B16.5 FlangeType Of Industrial flangesBlind Flange/ Slip On Flange/ Weld Neck Flange/ Socket Weld Flanges/ RTJ Flanges/ Lap Joint Flanges/ Threaded/ Reducing FlangesFlanges Manufacturing MaterialStainless Steel, Brass, Bronze, Duplex Steel, Super Duplex, Incoloy, Alloy 20, Copper, Carbon Steel, Nickel Alloys, Tantalum, Cupro-Nickel Inconel, Monel, Titanium, Hastalloy, Alloy Steel.Type Of Pipe Flange MethodsForging/ Casting/ Rolling And CuttingANSI Flange Pressure ClassClass 150/ Class 300/ Class 400/ Class 600/ Class 600/ Class 900/ Class 1500/ Class

Связаться сейчас

Butt welding ring loose flangeThe purpose of using butt welding ring loose flange is to save materials. The flange plate is made of low-grade material, and the pipe part is made of the same material as the pipe, so as to save material.Butt weld ring loose flange:1. Cost saving. When the pipe material is special and expensive, the cost of welding flanges of the same material is high.2. It is inconvenient for welding or processing or requires high strength. Such as plastic pipes, glass steel pipes and the like.3. Easy to construct.

Связаться сейчас

C-276 alloy welding performance and common austenitic stainless steel is similar to using a welding method for welding C-276 before, we must take measures to make the corrosion resistance of the weld and heat affected zone the smallest decline, such as tungsten gas shielded arc welding (GTAW), gas metal arc welding (GMAW), submerged arc welding or some other can make the weld and heat affected zone the smallest decline in corrosion resistance welding method.

Связаться сейчас

We mainly produce the Carbon and Alloy Steel Flanges, Nickel Alloy Steel Flanges, Stainless Steel Flanges. Here are the main types of the Flanges that we can supply for you.

Связаться сейчас

ER308,ER308L,ER308Si,ER308LSi,ER309,ER309L,ER310,ER316,ER316L;AWS: A5.9Conforms to Certification: AWS A5.9 ASME SFA A5.9Weld Process Used for Mig (GMAW) and Submerged Arc (SAW)AWS Chemical CompositionC = 0.08 maxCr = 19.5 – 22.0Ni = 9.0 – 11.0Mo = 0.75 maxMn = 1.0 – 2.5Si = 0.30 – 0.65P = 0.03 maxS = 0.03 maxCu = 0.75 maxAvailable SizesDiameter X Spool SizesDiameter X Coil Sizes.025 x 2#, 10#, 25#1/16 x 60# & mill coil.030 x 2#, 10#, 25#, 30#, 33#5/64 x 60# & mill coil.035 x 2#, 10#, 25#, 30#, 33#3/32 x 60# & mill coil.045 x 2#, 10#, 25#, 30#, 33#1/8 x 60# & mi

Связаться сейчас

430 stainless steel is a general-purpose steel with good corrosion resistance. It has better thermal conductivity than austenite, a smaller thermal expansion coefficient than austenite, heat fatigue resistance, addition of stabilizing element titanium, and good mechanical properties at the weld. 430 stainless steel is used for building decoration, fuel burner parts, household appliances, and home appliance parts. It is mainly used for automatic lathes, bolts and nuts.

Связаться сейчас

Hastelloy C-4 Seamless PipeHastelloy C-4 alloy is a nickel-chromium-molybdenum alloy with outstanding high-temperature stability as evidenced by high ductility and corrosion resistance even after aging in the 1200 to 1900°F (649 to 1038°C) range. This alloy resists the formation of grain-boundary precipitates in the weld heat-affected zone, thus making it suitable for most chemical process applications in the as-welded condition.

Связаться сейчас

Hastelloy C-4 alloy is an austenitic low-carbon nickel-molybdenum-chromium alloy. The main difference between Nicrofer 6616 hMo and other early-developed alloys of similar chemical composition is the low carbon, silicon, iron, and tungsten content. Such a chemical composition makes it exhibit excellent stability at 650-1040°C, improves the ability to resist intergranular corrosion, and can avoid edge line corrosion sensitivity and weld heat-affected zone corrosion under appropriate manufacturing conditions.

Связаться сейчас

FeaturesCorrosion Resistance: 2205 stainless stands-up excellently in a range of atmospheric environments even when exposed to corrosive elements, specifically to sea water.Heat Resistance: Generally, 2205 is not suitable for use at temperatures above 300°C as it suffers from precipitation of brittle micro-constituents.Avoid temperatures below -50°C because of its ductile-to-brittle-transition.Easy to weld with excellent weldability.The high strength of 2205 also makes bending and forming more difficult.Product Parameter:NameStainless Steel angle barStandardASTM A276, A484, A479, A580, A582, J

Связаться сейчас

ASTM A182 F11 F22 F5 F304 F316L F53 Stainless Steel Duplex Stainless Steel Slip on Flange So RF Flange Weld Neck Flange Blind FlangeItemDescriptionBasic InformationMaterial GradeWP304 , WP304L , WP304H , WP316 , WP316L , WP316Ti , WP309S , WP310S , WP321 , WP321H , WP347 , WP347H , F304 , F304L , F304H , F316 , F316L , F310S , F321 etcSize1/2" to 48" Sch 5S to XXSStandardASTM A403 etc .Process MethodForged / CastingIndustry & AdvantageApplicationa) Connect pipesAdvantagea) High technology ; good surface ; high quality etcTerms & ConditionsPrice ItemFOB , CFR , CIF or as

Связаться сейчас

SL Food Grade 19mm/25/32/38/45/51mm OD Sanitary Butt Weld 90 Degree Elbow Bend Pipe 304 stainless steel FittingProduct Description of Stainless Steel ElbowPIPE FITTINGSProduction Name45 / 90 / 180 , Long / Short Radius Elbows, Equal / Reducing Crosses, Concentric / Eccentric Reducers, Caps, Stub EndsSize RangeFrom ½" up to 72" From 1/2 to 30 (Seamless Pipe Fittings),Form16to 72(Seam Pipe Fittings)Sched

Связаться сейчас

316L stainless steel h beam has low cost, high precision, low residual stress, no expensive welding materials and weld inspection, and can save about 30% of steel structure production cost.Product Parameter:Product namestainless steel H-beam / I-beamStandardJIS, AiSi, ASTM, GB, DIN, ENSize100mm-900mmWall thickness1.5mm-28mmMaterial grade301 303 303Cu 304 304J1 304L 316 316L 309S 310S 316Ti 321 430 420 410 409L 904LApplicationHardware products, medical machinery, food machinery, ships, cars, doors and Windows, furniture, large machinery, etcProcessing ServiceBending, Welding, Decoiling, Pu

Связаться сейчас

Alloy B-2 is a nickel-molybdenum alloy with significant resistance to reducing environments, such as hydrogen chloride gas and sulphuric, acetic and phosphoric acids. Hastelloy® B-2 provides resistance to pure sulphuric acid and a number of non-oxidizing acids. The alloy should not be used in oxidizing media or where oxidizing contaminants are available in reducing media.

Связаться сейчас

Application is very wide, below 980 ℃ has sufficient strength and corrosion resistance and oxidation resistance.1.Manufacture of springs and bolts working under high temperature; rotor blades, impellers and other structural parts of gas turbines;2. Thrust chamber on rocket engines;3. Thrust reversal device on aircraft;4.

Связаться сейчас

Alloy X-750 exhibits excellent oxidation resistance to combustion gases at ambient temperatures up to 1600°F(870°C).Product Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm (All sizes can be customized)Forged Bar: 180~400mmLengthCustomizedApplicationAuto, turbines, blades, powder and engines,etcFeatureHi

Связаться сейчас

The chemical composition of Monel400 alloy is mainly composed of 30%Cu and 65%Ni plus a small amount of Fe(1%-2%). The structure is typical monophasic austenite.

Связаться сейчас

Alloy K-500 (UNS N05500) is a nickel-copper alloy.

Связаться сейчас

Alloy 400 from NeoNickel has superb corrosion resistance, particularly in neutral and alkaline salts. It is also one of a limited number of alloys that can be used in conjunction with hydrofluoric acid and fluorine. With high nickel content, this alloy is immune to chloride-induced stress corrosion cracking.

Связаться сейчас